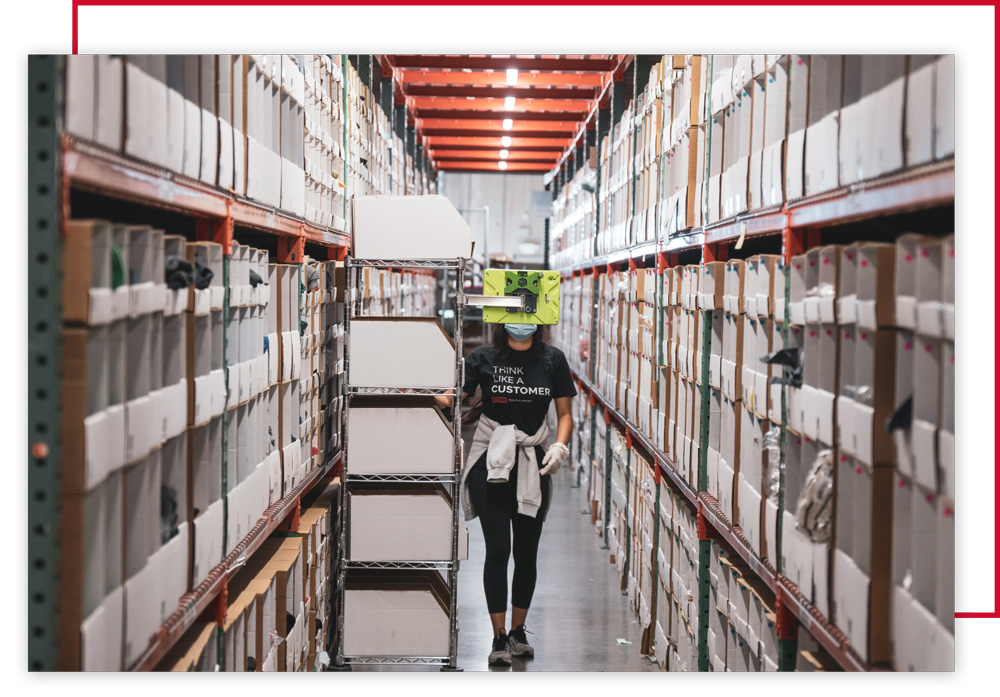

INVENTORY MANAGEMENT

AN INSIDE LOOK

Inventory Management combines the tasks of ordering, receiving, storing, selling, and shipping inventory by SKUs and locations in real-time to create a transparent logistics operation that every party along the supply chain can follow.

Handling inventory through a Custom Warehouse Management Software (WMS) “like DriveLine” aligns manufacturing and delivery lead times to help plan for when merchandise is en-route from the supplier, delivered to the customer, and returned from customers in real-time.

STAY INFORMED

Automating and integrating your products with a fulfillment partner like Drive means eliminating time-consuming and inefficient manual inventory tracking keeping you ahead and informed. Tracking and maintaining healthy inventory levels keeps customers happily shopping with you, rather than looking to other competitors with available inventory.

FEATURES

- Categorization of products in stock

- Measurement of products

- Inventory and product history

- Cycle counting

- Live stock reports and audits

- Merchant management

- eCommerce integrations

- Complete Inventory management

THE PROCESS:

01

DELIVERED & STORED

Upon delivery, your merchandise is reviewed, sorted, and systematically stored by SKU in specific stock areas.

02

INVENTORY MONITORED

03

ORDERS PLACED

Orders are placed by customers, internal or external.

04

GOODS PICKED

Once approved, the required goods are pulled, packed, and shipped to either the appropriate end customer (finished goods) or business unit/department (internal requests)

05

INVENTORY UPDATED

Updated inventory levels and usage data make it easy to automatically restock goods and the required materials in creating accurate forecasts for the future.

STAY INFORMED

Stay informed and on top of your inventory today with a transparent logistics process that every party along the supply chain can follow with Drive Fulfillment.