Whether you are tending to a business venture or living organism, nourishing something from its inception requires a perfect mix of expertise, organization, tactfulness, and passion to get things off the ground and keep them running smoothly. While a will to succeed is essential in chasing down your small business dreams, grasping the core of inventory logistics and supply chain management is imperative to staying ahead of competitors and increasing your bottom line.

A smart and comprehensively built inventory management system gives you an inside look at the health and performance of your eCommerce store. In the simplest of terms, inventory management includes the process of ordering, receiving, storing, selling, and shipping a company’s inventory. More than that, it involves the management of raw materials, components, in addition to the finished products.

The secret to a successful eCommerce operation is getting the right products into the hands of the right customers in the most convenient, efficient, and timely manner. Understandably, grasping the pulse and flow of inventory is essential to channeling profitability. Wouldn’t it be nice to minimize overhead stock costs from excess inventory while avoiding problematic out-of-stock scenarios? Before we dive into some best practices for inventory management, evaluate the following questions:

- Are you losing money because of excess stock?

- Are you losing sales opportunities due to out-of-stock issues?

- How many products should you be buying?

- What are your worst and best-selling products?

Tips to Manage Inventory for Small Business

Perform Regular Stock Audits

Whether you have the technological or automation capabilities to perform regular audits or not, they are a necessary part of understanding what you have in stock, what is sold, and what people passed up. Without routine monitoring, it becomes difficult to grasp growth trends, pinpoint areas of improvement, and make appropriate pivots.

Identify what you are trying to achieve, how well you are moving towards that goal, and what could be changed to improve results. Once the stock data has been collected and analyzed, re-evaluate the validity of the audit insights through continued monitoring. Mix in a spraratic inventory count every now and again, making an effort to complete at least one on an annual and quarterly basis. This is when partnering with a qualified fulfillment or 3PL provider can relieve the constant stress and worry of not knowing where your stock and inventory levels lie and what they indicate on a larger scale. With a team of fulfillment experts and a transparent real-time warehouse management software guiding logistics, all your insights and answers are a few clicks or email away.

Pinpoint Best & Worst Sellers

No matter the product or service, a dynamic quality control protocol fosters customer loyalty and keeps them coming back for more. Your products must look great and function as intended to create a memorable and lasting first impression. Whether a team of employees verifies quality as orders ship or during the audit phase, make sure that quality control is a priority.

Emphasize Quality Control

No matter the product or service, a dynamic quality control protocol fosters customer loyalty and keeps them coming back for more. Your products must look great and function as intended to create a memorable and lasting first impression. Whether a team of employees verifies quality as orders ship or during the audit phase, make sure that quality control is a priority.

Categorize Inventory

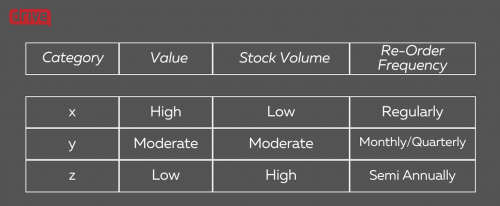

Since inventory audits often illuminate trends and patterns that are otherwise difficult to discern, take it a step further and rank your inventory based on value and volume. Pair similar valued items into high, moderate, and low-value categories with corresponding stock volumes as such.

Forecast Demand

Categorizing and auditing stock not only improves visibility and illuminates consumer trends, but also facilitates demand forecasting. The more precise you are, the less money wasted on the unsold stock in the long run. Given average yearly costs of holding excess inventory can top 25%, forecasting demand based on past sales, market trends, and inventory patterns is imperative.

As time goes on, begin to forecast trends using niche market and customer insights to increase accuracy. While many outward marketing efforts focus on spending more to acquire more conversions, small businesses need to understand where and how to cut excess costs. Especially when it comes to inventory management, this will put more money back in your pocket than you initially expected.

Use Appropriate Automation

In the simplest of terms, eCommerce automation focuses on optimizing or eliminating manual processes or tasks necessary to running an eCommerce store. Programmed workflows, automated software, and app integrations significantly lighten your workload.

An advantage of eCommerce automation is that it increases the speed at which you can effectively scale your business. Even though hiring a team of people to work on manual tasks may appear to be less overall work, testing and creating automated workflows that function on autopilot is often always worth the allocated time and effort in the long run.

The ultimate goal of these automated processes is to reduce the overall workload of individual teams and employees. This approach also strategically awards more time for business owners to focus on the most critical tasks at hand.

Implement FIFO

A first-in, first-out (FIFO) approach to inventory management means that assets purchased or acquired first, are then disposed of first. Using FIFO, the remaining inventory is composed of items purchased last. The intended purpose of implementing a FIFO approach is to reduce losses and potential waste, especially if you are in the business of selling perishable items like makeup, food, or fashion, all of which depreciates quickly.

Besides grasping which items are new and old, chronologically sorting items in this fashion helps to spot theft and potential inventory manipulation. Not only does a FIFO approach help facilitate a routine and predictable turnover rate, but it also helps keep your balance sheet closer to market values. Since the market prices of stock you received months ago can change, FIFO helps to combat inflation to maximize profit.

Implement Inventory Tracking

Inventory tracking is an essential step in creating a transparent logistics operation that everyone along the supply chain can follow. More specifically, monitor and track product SKU’s, locations, and quantities of items in your possession.

A real-time view of inventory through a smart warehouse management software, like Driveline powered by Despostco, helps frame overall performance, eCommerce heath, and product availabilities. Tracking and maintaining healthy inventory levels keeps customers happily shopping with you, rather than looking to competitors with available inventory. More than that, Inventory tracking systems such as Driveline help align manufacturing and delivery lead times to help plan for when merchandise is en route from the supplier, delivered to the customer, and returned from customers. Since the manual process of tracking inventory can be extremely time-consuming and inefficient, it pays to automate and integrate with a fulfillment partner like Drive.

Conclusion

Naturally, the more cost-effective and efficient your supply chain management solutions are, the happier you and your customers will be. Although end customers may not have an idea or total view of the logistical process, they are beneficiaries.

At Drive Fulfillment, we believe that no two customers are the same and neither should their fulfillment process be. As a result, we build customized solutions optimized for your business, no matter the size. For more information regarding tours, pricing, shipping capabilities, or explore 6 Benefits of Outsourcing eCommerce Store Fulfillment, contact us, or visit the Drive Fulfillment blog today.